Products

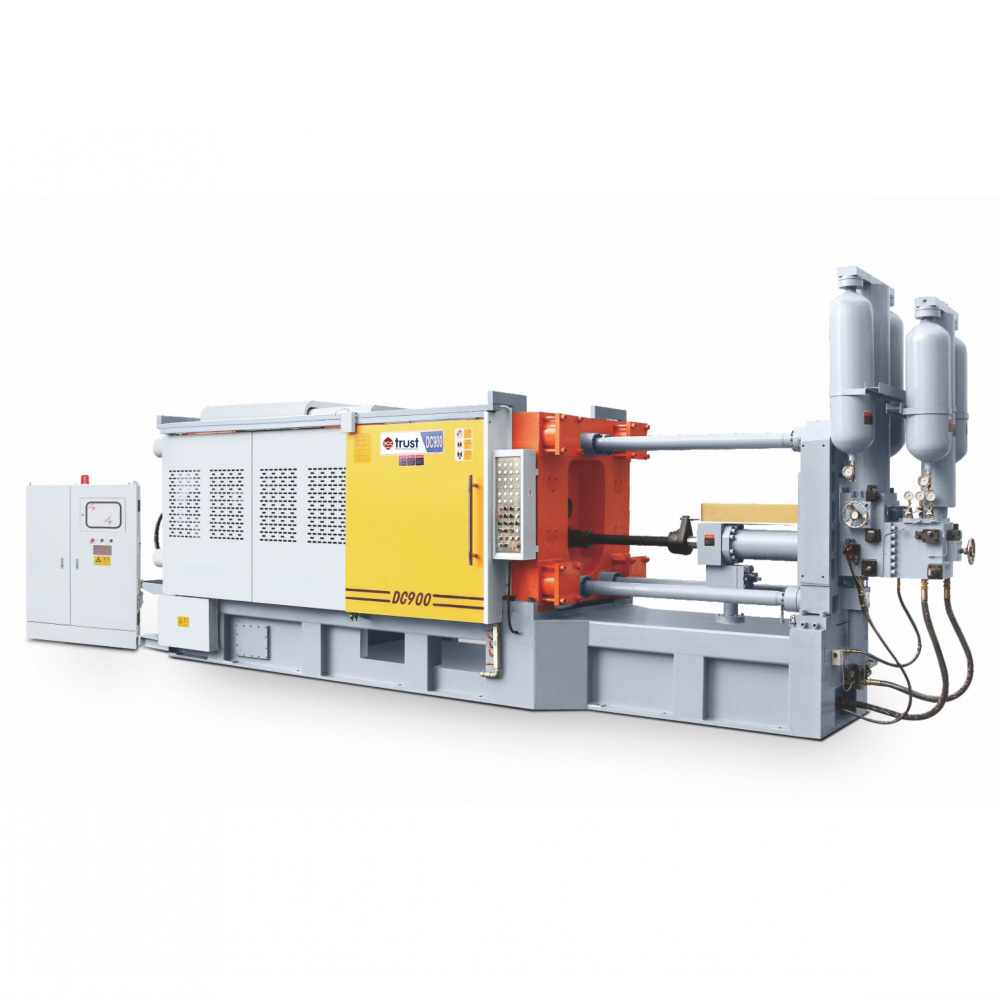

2500Ton Precision Yakakwira Kudzvanya Aluminium Alloy Cold Chamber Die Casting Machine

Features

1. Iyo mold platen zvinhu inogadzirwa nenodular cast iron uye yakakosha alloy zvinhu. ine ductility yakanaka uye inogona kutora zvirinani simba rekuita jekiseni; Kuoma kwepamusoro pepamusoro, zvinobudirira kuderedza kufa extrusion uye maitiro emakaki. Iyo formwork inotora yakakora dhizaini kuti ive nechokwadi chekuti iyo formwork pamusoro haisi nyore kudonha uye kutsemuka panguva yekushandiswa kwenguva refu.

2. Iyo inofambiswa mold platen inotora mbabvu yeplate yekugadzira dhizaini, iyo isingango wedzera simba repakati ndiro kubva muchimiro, asi zvakare inogadzirisa nhevedzano yezvinetso zviripo mune yakamiswa thimble chimiro chinowanzoshandiswa muindasitiri.

3. Majoini ese anofamba emuchina achapihwa alloy simbi gwenzi, uye nemvura yenitrogen inotonhora yekuchaja process, iyo yakabatana kudzvinyirirwa ichave yunifomu, kuitira kuti ibudirire kuwedzera hupenyu hwebasa remuchina.

4. Zvinoenderana neyakajairwa dhizaini yemuchina unotengeswa kunze kwenyika, yepakati frequency processing inogamuchirwa kune tambo ye-tie-bar, iyo inovandudza kuomarara uye kupfeka kusagadzikana kweiyo tambo mbiri, uye inogadzirisa matambudziko akajairika ekugadzirisa mold uye tambo yeshinda muindasitiri. .

5. Chigadziko chemuchina chinotora chimiro chesimbi chakaumbwa neI uye chinowedzera chimiro chesimbi chesimbi. Yakasanganiswa nekupisa kwekurapa maitiro, ine zviri nani kuomarara uye haisi nyore kukanganisa, inonyatso kuchengetedza iko kurongeka kwekushandisa kwenguva refu yemuchina.

6. Iyo yakakosha alloy zvinhu uye kupisa kupisa maitiro anogamuchirwa kune tie-bar, uye yakatwasuka uye yakatwasuka nzira mbiri-kushushikana kuburitsa sisitimu inowedzerwa kuti ive nechokwadi chekutsiga kusimba kwesimba remuchina wese uye kurebesa hupenyu hwesevhisi ye-tie- bar.

7. High performance jekiseni system, ine jekiseni rinoshanda uye yakananga kudzvanywa chimiro, yakashongedzerwa nepamusoro-inoshanda simba rekuchengetedza sisitimu, inokwenenzvera dunhu remafuta ejekiseni system, inoderedza kurasikirwa munzira yekufambisa simba, kukurumidza kwejekiseni kunosvika 60g, uye inovandudza zvakanyanya kugadzikana uye kudzokorora kweakakosha paramita. Uye zvakare, iyo jekiseni system ine otomatiki simba rekuchengetedza basa, otomatiki kuverenga uye kuenzanisa basa rekuchengetedza simba kumanikidza, kudzvanya kutadza alarm basa, nitrogen leakage alarm basa, otomatiki kuburitsa basa, nezvimwe.

8. Cartridge valve kuvhura gadziriso yemagetsi, yakazvigadzira yega cartridge valve yekuvhura kugadzirisa, yakagadzirisa matambudziko ehunyanzvi ekugadzirisa kuoma muindasitiri.

9. Chimiro chechimiro chinotungamirirwa neboka repasi rose rekugadzira maindasitiri rakapa dhizaini yevanoda kusvika 2000 vatengi pasi rose, ine chitarisiko chikuru uye chinoshanda.

Pfungwa huru

PLC Kudzora System

Iyo PLC inotora Omron / Siemens ruvara inoratidzira yekubata sikirini uye yekugadzira intelligence mashandiro ekutonga.

Jekiseni System

Iyo yakanyatsogadzirwa jekiseni control system, ine maparamendi anochinjika, akakodzera kugadzirwa kweakasiyana emhando yepamusoro zvigadzirwa.

Hydraulic Control System

Kaviri proportional control oiri dunhu, kudzvanywa uye kumhanya zvinogona kugadziriswa otomatiki.

Clamping System

Yakakwira simba rekushandura dhizaini dhizaini inovimbisa kugadzikana uye kusimba kwemashini base. Ukobvu uye kushandura zvakasimbiswa, uye sleeve yemutungamiri weplate yepakati inorebeswa ne30%, iyo inovimbisa kugadzikana kwepamusoro uye kuenzana kwekushanda kwe mold platen.

Lubrication System

Central otomatiki lubrication system, nguva yekuzora toggle, kunatsiridza hupenyu hwemakanika uye kuderedza kugadzirisa.

Ejection System

Yakakwirira simba mechanicha chimiro, kaviri ejector silinda (≥300Ton).

Cheka dhizaini yedunhu remafuta kuti uve nechokwadi chekushanda kwakagadzikana kwehydraulic system.

General tekinoroji

Servo Motor Energy Saving System / Oiri Kutonhora System (sarudzo)

1. Kubudirira kwepamusoro uye kugona mukuchengetedza simba

Muchina wekukanda wekufa unogadzirisa otomatiki kuyerera kunoenderana nekumisikidza komputa. Iyo yese simba rekuchengetedza simba rinogona kusvika 45% ~ 75%.

2. Mutsindo wakaderera

Ruzha panguva yekushanda yakajairika isingasviki 65dB, kuwana runyararo kushanda uye kugadzirisa nharaunda yekushanda.

3. High speed mhinduro

Iyo yakazara sisitimu ine simba yekupindura nguva iri pasi pe50ms, uye kugona kwekugadzira kunowedzerwa ne5% kusvika 7% pamusoro peakajairwa modhi.

4. High-precision control

Iyo PID gadziriso yekuyerera kwehurongwa uye kudzvanywa neoiri-yakatonhorera servo mutyairi inoita kuti iyo inodzokororwa chaiyo yeoiri system yese inodzorwa mukati me0.3% kuve nechokwadi chemhando yechigadzirwa.

5. Kuwedzera kwehupenyu hwebasa

Iyo yakapetwa kaviri yakavharwa loop yekuyerera kuyerera inoita kuti muchina umhanye zvakatsiga uye nekukwirira kudzokororwa, kudzikisa zvakanyanya kurova, kusunungura kupfeka kweakasiyana zvikamu uye kurebesa hupenyu hwesevhisi.

Real Time Yakavharwa Loop Injection Control System (sarudzo)

Jekiseni ine chaiyo nguva inogadziridzwa yemakiyi ma paramita kuti ive nechokwadi chepamusoro maitiro kugadzikana uye nemazvo.

1. Kugara kumhanyisa kwe1st Phase velocity

Yakagadziridzwa 1st chikamu kudzikisa kana kudzivirira kuvharirwa kwemhepo panguva yekuzadza-kusati kwasvika.

2. Yakananga uye nekukurumidza chinja kune kukurumidza kuzadza chikamu

Precise switch kune kukurumidza kuzadza kuti uwane iyo yakanakira jekiseni maitiro.

3. Kurumidza uye chaiyo chinja-pamusoro kune intensification chikamu

Inokurumidza uye chaiyo inokonzeresa yekuwedzera chikamu kubvumira kukurumidza kumanikidza kuvaka nguva.

4. Speed brake pamagumo ekuzadza cavity

Braking mukumhanyisa jekiseni, haingodzikisi flash kuvaka asi zvakare inowedzera kufa sevhisi hupenyu.

| DC2500 Cold Chamber Die Casting Machine Specification List | |||

| Item | Unit | DC2500 | |

| Clamping Unit | Clamping force | KN | 25000 |

| Clamping sitiroko | mm | 1500 | |

| Nzvimbo pakati pemabhawa (HxV) | mm | 1500 × 1500 | |

| Platen size(HxV) | mm | 2350×2350 | |

| Tie bar diameter | mm | 310 | |

| Mold ukobvu | mm | 700-1800 | |

| Ejection force | KN | 750 | |

| Ejection sitiroko | mm | 300 | |

| Jekiseni Unit | Jekiseni simba | KN | 1800 |

| Jekiseni sitiroko | mm | 1100 | |

| Jekiseni nzvimbo | mm | -200.-400 | |

| Plunger dhayamita | mm | 140-180 | |

| Jekiseni uremu(AL) | Kg | 30-55 | |

| Jekiseni uremu(MG) | Kg | 21.6-39.6 | |

| Kukanda pressure (pressurized) | Mpa | 115-70 | |

| Nzvimbo yekukandira | CM2 | 2150-3500 | |

| Max. nzvimbo yekukanda (40MPa) | CM2 | 6250 | |

| Plunger kupinda | mm | 450 | |

| Sleeve flange dhayamita | mm | 280 | |

| Sleeve flange inobuda kureba | mm | 30 | |

| Vamwe | System pressure | MPa | 16 |

| Motor power | KW | 135 | |

| Oiri tank kukwanisa | L | 3000 | |

| Machine uremu | Ton | 165 | |

| Muchina dimension(L×W×H) | mm | 14000x4600x4500 | |

| DC SERIES COLD CHAMBER DIE CASTING MACHINE STANDARD & ZVINODA ZVINODA | |||||||||||||||

| Configuration chinhu | DC180 | DC238 | DC300 | DC350 | DC380 | DC400 | | DC550 | DC700 | DC900 | DC1000 | DC1300 | DC1650 | DC2000 | DC2500 | DC3000 |

| Clamping Unit | |||||||||||||||

| Kaviri kuenzanirana kudzora kwe mold kuvhura & kuvhara | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Proximity switch control yekuvhura sitiroko | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Stroke transducer control yekuvhura sitiroko | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο |

| Fast speed mold pedyo | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Manual mold kugadzirisa | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Automatic mold kugadzirisa | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο |

| Jekiseni Unit | |||||||||||||||

| 2nd jekiseni + rinowedzera handwheel kugadzirisa kutonga | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Magetsi proportional kugadzirisa control | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο |

| Proximity switch control sitiroko | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Inosimbisa activation position & pressure control | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Ejector uye core pulling unit | |||||||||||||||

| Promixity switch control ejection sitiroko | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Single ejection eyeliner | ● | ● | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο |

| Kaviri ejection eyeliners | - | - | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Core puller-1 set pane inofambiswa platen | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Core puller-2sets pane inofambiswa platen | - | - | - | - | - | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Core puller-1 yakaiswa pane yakagadziriswa platen | Ο | Ο | Ο | Ο | Ο | Ο | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Core puller-2sets pane yakagadziriswa platen | - | - | - | - | - | - | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Magetsi unit | |||||||||||||||

| Omron PLC / Siemens PLC | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 7 inch high resolution touch screen | ● | ● | ● | ● | ● | ● | ● | ● | ● | Ο | Ο | Ο | Ο | Ο | Ο |

| 10 inch high resolution touch screen | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | ● | ● | ● | ● | ● | ● |

| Vamwe | |||||||||||||||

| Alarm device | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Plunger lunbrication unit | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο |

| Mashoko: 1. ● Standard Ο Sarudzo - Kwete Kushandisa 2.Tinochengetedza kodzero yekuita chero chigadzirwa chekuvandudza kana chirevo chekuchinja pasina chiziviso chekutanga. |

|||||||||||||||